Dot peen marking is a popular method of permanently marking metal and plastic components in the manufacturing industry. Dot peen marking is a powerful method for permanently marking metal and plastic components in the manufacturing industry. It offers several benefits, including high-speed marking capabilities, compatibility with a wide range of materials, and tamper-resistant markings.

What is Dot Peen Marking?

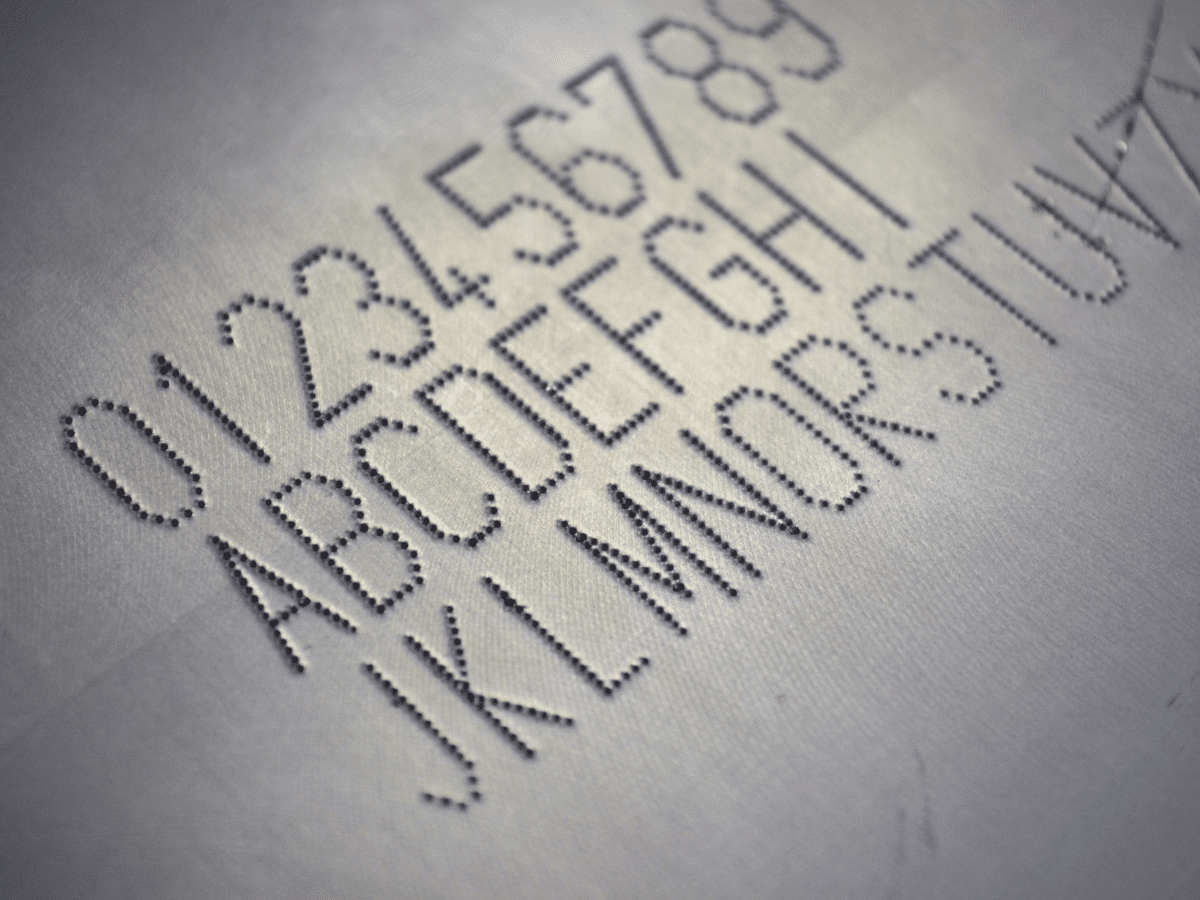

Dot peen marking, also known as dot marking or micro-percussion marking, involves using a specialized machine to create indents on the surface of a part. The machine works by rapidly striking a carbide-tipped stylus against the part, creating a series of small dots that form letters, numbers, and symbols.

Benefits of Dot Peen Part Marking

Dot peen marking offers several benefits over other marking methods, including:

- Permanent and tamper-resistant markings that cannot be easily removed or altered

- High-speed marking capabilities for efficient production

- Compatibility with a wide range of materials, including metals, plastics, and composites

- High-quality and precise markings that are easy to read and scan

How is Dot Peen Part Marking Used in Automated Production Machining?

Dot peen marking is commonly used in automated production machining to ensure accurate and consistent marking of parts. Automated dot peen marking machines are integrated into the production line, allowing for high-speed marking of parts without the need for manual intervention.

The process begins with the creation of a marking file that specifies the information to be marked on the part. The marking file is then uploaded to the dot peen marking machine, which uses its carbide-tipped stylus to create the markings on each part as it passes through the production line. Dot peen marking machines can be programmed to mark a variety of information that allows for easy tracking and identification of parts.

Part identification – Dot peen marking can be used to permanently mark parts with unique identification codes, serial numbers, and other essential information. This helps to track parts during the manufacturing process and ensures that they are properly identified during maintenance and repair.

Traceability – In the aerospace industry, dot peen marking is used to provide permanent markings on parts, such as engines, landing gear, and fuselage components. This helps to ensure that the parts are traceable and can be easily tracked throughout their lifecycle.

Quality control – A reliable method for ensuring consistent quality control, manufacturers can quickly identify and remove defective parts from production thanks to marking critical components with part numbers, batch codes, and other information

Regulatory compliance – Many components used in the oil and gas and aerospace industries must meet strict regulatory standards. Dot peen marking can be used to mark parts with relevant information such as batch numbers, material type, and other compliance-related data.

Damage prevention – Dot peen marking is used to mark sensitive and expensive equipment to prevent damage and theft. Marking equipment with unique identifiers such as serial numbers and company logos helps to deter theft and ensures that lost or stolen equipment can be easily identified.

Maintenance tracking – In the aerospace and defense industries, dot peen marking is used to keep track of the maintenance history of critical components such as engines, landing gear, and avionics. By marking parts with dates, service records, and other relevant information, maintenance personnel can quickly and easily determine when maintenance is required and ensure that it is performed on schedule.

Coastal Machine and Supply – Your Partner for Automated Production Machining

At Coastal Machine and Supply, we specialize in CNC machining for clients in the oil and gas, aerospace, and defense industries. Our state-of-the-art facility includes advanced marking machines (including laser marking) that allow us to provide high-quality, permanent markings for our clients’ parts.

We offer a wide range of CNC machining services, including milling, turning, drilling, and more. Our team of experienced machinists and engineers is dedicated to providing our clients with exceptional service and quality results. Contact us today to learn more about our services and how we can help you with your CNC machining needs.