IT’S ALL IN THE FINISH

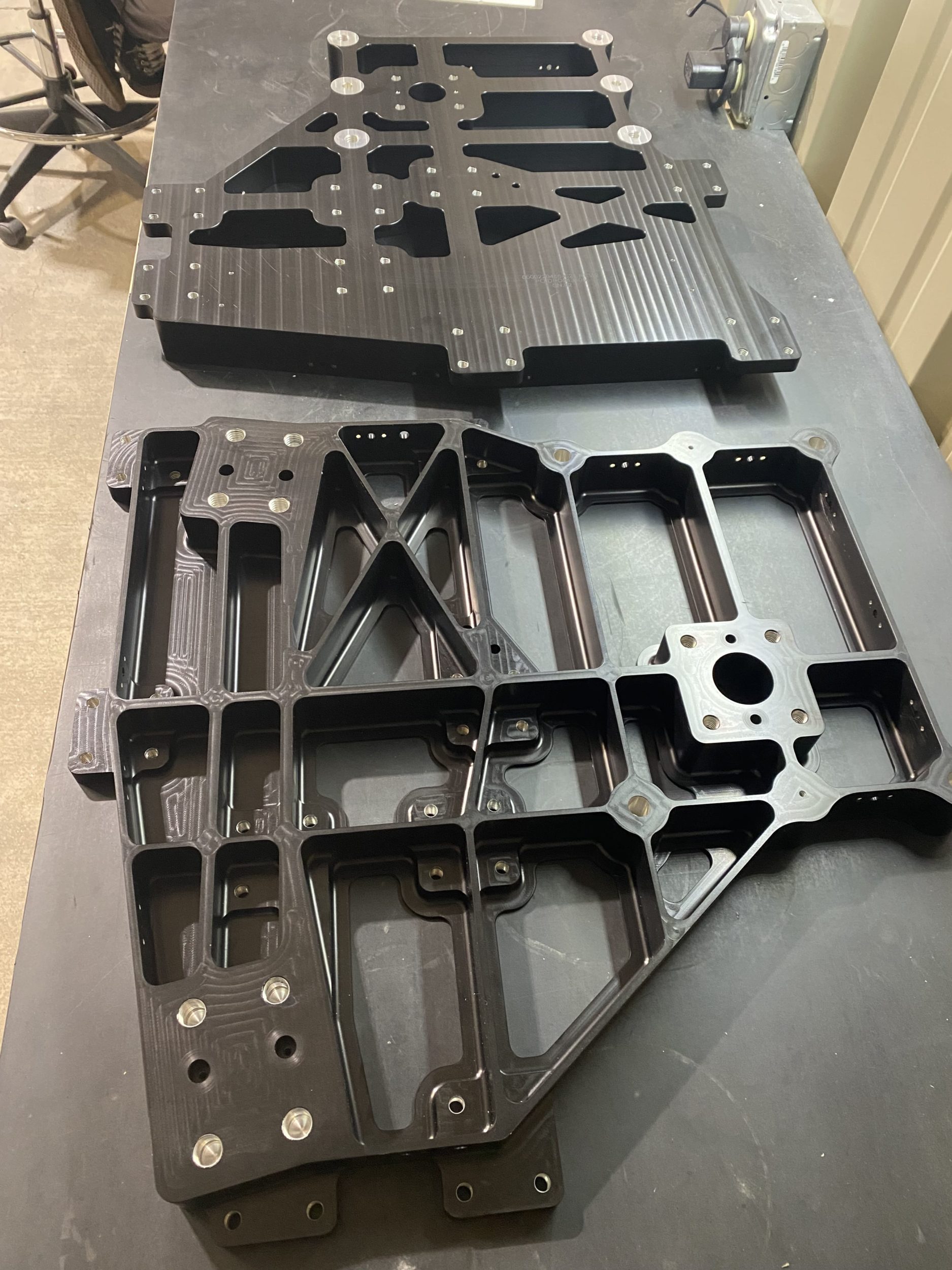

Black Anodizing is a process that is applied to improve corrosion and wear resistance on aluminum that has been CNC machined. This results in a product that is stronger than traditionally anodized aluminum and performs at higher light and heat exposure. While anodizing can be used to strengthen aluminum, the use of black anodizing creates products that can perform in situations that are unsafe for products that have not been constructed from anodized aluminum. With an exceptionally durable finish, anodized aluminum has been used in architecture, transportation, consumer goods and much more. Before we get into the full benefits of upgrading your aluminum designs with the use of black anodizing, though, let’s review the process of anodizing aluminum.

WHAT IS ANODIZING?

During the anodizing process, the aluminum surface is coated with an oxide layer that is applied through an electrochemical process. By connecting the part to an anode and submerging into an acidic electrolyte bath solution, the voltage sent by a cathode attracts positive ions, leaving the part porous and allows for a reaction with the negative ions to create a layer of aluminum oxide on the surface of the part. Providing additional strength, this process also creates a more desirable surface finish in addition to increasing its durability. It is possible to control the finished color of the product by dipping it into a dye solution after the initial anodizing is complete, filling the pores of the product with the desired color. While you can use black dye, this is not the most effective method of black anodizing, as the color and protective qualities may degrade over time.

WHAT IS BLACK ANODIZING?

Black anodizing increases the thickness of the natural oxide layer on the surface of the aluminum used to mill various products, with a chemical process being used to create a smooth surface finish. Inorganic metallic salts are added during the anodizing process that further change the metal’s structure, making it a superior method of achieving a black anodize finish compared to the use of black dye. Rather than an applied finish, such as dye, achieving the finish through the use of metallic salts is the result of a chemical reaction between the salts and the metal that can create a finish that is as much as 30% thicker than the aluminum alone.

Metals that have been anodized are better suited for use in situations with high heat and extreme light, with black anodized materials exceptionally suited for use with spacecraft, optical devices, and healthcare equipment. In addition to performing as semiconductors or when exposed to electricity, in each of these situations, black anodizing increases the resistance to high heat and strong cleaning products.

BENEFITS OF BLACK ANODIZING

- Finishes resist peeling, flaking, and chipping

- Products are easier to clean and maintain

- Finishes are resistant to fading and corrosion and easily lubricated

- Production process is consistent, efficient, and requires a short lead time

Achieved through a process that is environmentally friendly as well as aesthetically pleasing, machine shops will use black anodizing on parts that are milled for use in the Aerospace industry to increase its tolerance to extreme temperatures. Essentially upgrading the finish of your product with increased corrosion and wear resistance, there are a number of useful applications for products that have undergone the black anodizing process.

At Coastal Machine & Supply, we meet the changing needs of our clients with the latest technology and fully digitized processes that allows us to offer top of the line manufacturing for Aerospace, Defense, Oil and Gas industries and more! Trusted by domestic and international clients, we provide custom, precision machining utilizing the latest technologies and a state of the art facility for quick project turnaround.