Gone are the days when traditional machining methods solely relied on manual labor and conventional machinery. Today, robotic systems have emerged as indispensable assets, seamlessly blending automation with human expertise to optimize production processes.

Harnessing the power of robotics to elevate custom machining services to unprecedented heights, Coastal Machine & Supply recognizes the immense potential of robotics in enhancing the quality, speed, and flexibility of our custom machining services.

Precision Engineering and Versatility in Custom Machining

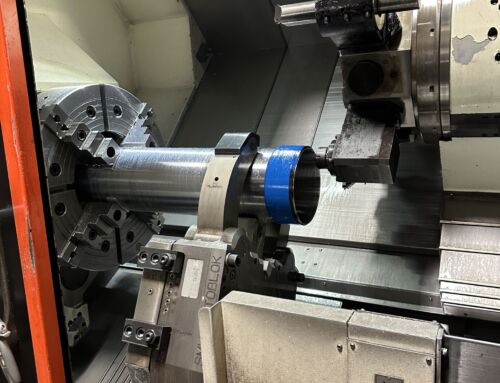

One of the key advantages of incorporating robotics into manufacturing is precision engineering. Robots equipped with advanced sensors and algorithms can execute intricate machining tasks with unparalleled accuracy, ensuring consistent quality across every component. Whether it’s milling, turning, or grinding, these robotic systems excel in achieving tight tolerances and complex geometries, meeting the most demanding specifications with ease.

Moreover, robotics in manufacturing drastically reduces cycle times and enhances productivity. By streamlining repetitive tasks and minimizing human intervention, machines can operate round-the-clock without fatigue or errors. This not only accelerates production schedules but also enables us to fulfill orders with greater efficiency, giving our clients a competitive edge in their respective industries.

The versatility of robotic systems further amplifies the capabilities of custom machining services. Unlike traditional equipment limited by fixed setups, robots offer unmatched flexibility to adapt to changing requirements and accommodate diverse production demands. Whether it’s rapid prototyping or high-volume production runs, these agile machines can seamlessly transition between different jobs, maximizing resource utilization and minimizing downtime.

Revolutionizing Safety Standards

Robotics revolutionizes safety standards in machine shops. With built-in sensors and safety protocols, robots ensure a secure working environment by mitigating risks associated with manual operations. This not only safeguards the well-being of our workforce but also enhances overall operational reliability, reducing accidents and costly disruptions.

Embracing robotics in manufacturing also paves the way for innovation and competitiveness. By investing in cutting-edge technologies, such as collaborative robots (cobots) and machine learning algorithms, Coastal Machine & Supply stays ahead of the curve, continuously pushing the boundaries of what’s possible in custom machining. From predictive maintenance to adaptive machining strategies, these intelligent systems empower us to deliver innovative solutions that exceed our clients’ expectations.

Seamless Integration with Digital Technologies

Robotics facilitate seamless integration with other digital technologies, such as computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This interconnected ecosystem enables real-time data exchange and optimization, fostering a digital twin approach where virtual models mirror physical processes, allowing for simulation and analysis before actual production. As a result, we can iterate designs faster, minimize material waste, and optimize machining parameters for optimal performance.

Cost Savings and ROI

In addition to operational efficiency, robotics in manufacturing offer substantial cost savings over the long term. While the initial investment may seem significant, the return on investment (ROI) quickly becomes evident through reduced labor costs, enhanced throughput, and improved quality control. By automating repetitive tasks and optimizing resource allocation, Coastal Machine & Supply can deliver custom machining services at competitive prices without compromising on quality or lead times.

Driving Innovation

Looking ahead, the role of robotics in modern machine shops will continue to evolve, driven by advancements in artificial intelligence, sensor technology, and digital connectivity. As pioneers in the industry, Whether it’s revolutionizing production processes, empowering workforce development, or fostering sustainable manufacturing practices, robotics will undoubtedly play a pivotal role in shaping the future of manufacturing.

From precision engineering and enhanced productivity to safety compliance and cost efficiency, robotics offer a multitude of benefits that are reshaping the manufacturing landscape. At Coastal Machine & Supply, we embrace these transformative technologies wholeheartedly, striving to deliver unparalleled value to our clients while driving innovation forward in the ever-evolving world of manufacturing.