Technology plays an important role in manufacturing, especially when it comes to the volume production of parts with complex geometries, tight tolerances, or critical functions. Quotes need to be accurate. Dimensions need to be precise. Production times need to be efficient.

And without the right technology, none of this is possible — especially at scale.

At Coastal Machine & Supply, we leverage advanced industry-specific software, high-end machines, as well as robotics and automation to ensure that the parts we manufacture exceed expectations. But more than just the parts we manufacture, the technology we rely upon also ensures that our people and operations stay connected, production remains on schedule, and — most importantly — our customers have the best experience possible.

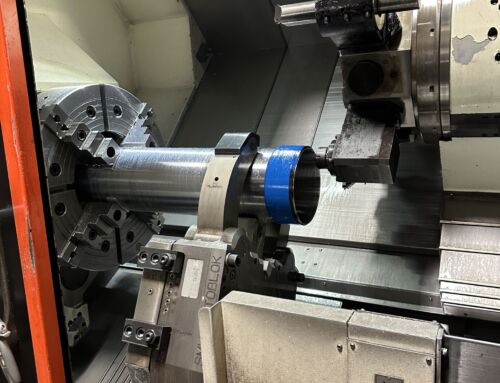

Investing in Advanced CNC Machines & Inspection Equipment

When making an important decision like deciding which CNC machines to purchase, we balance expanding our capabilities with increasing our production capacity. To do this, we invest in high-end equipment that offers outstanding accuracy and repeatability, as well as exceptional throughput. Not only does this make production more efficient on our end, but it allows us to better serve our customers by being able to provide precision CNC machining services for larger or longer parts, manufacture more complex designs, and offer shorter lead times.

Additionally, to manufacture parts that require absolute precision, we also offer CMM inspection. With our Hexagon bridge coordinate measuring machine (CMM), we are able to confirm and report on the dimensional accuracy of your parts to within three microns (3µm), including for parts with incredibly complex geometries or tight tolerances. While using a CMM does add cost and lead time, it’s by far the most reliable way to confirm a part’s accuracy.

Connecting Our Operations With Industry-Leading Software

While high-end machines are efficient, without the proper software, this efficiency would be lost to time-consuming and often imprecise manual processes. That’s why, at Coastal Machine & Supply, we leverage the capabilities of industry-leading manufacturing software, including Paperless Parts, ProShop, Mastercam, Datanomix, and HighQA to create end-to-end efficiency and traceability, ensuring that:

- All of your customer and part data is processed and stored in compliance with ITAR security requirements;

- Details about your part designs and production needs are available to the engineers and machinists who work on your parts;

- We are able to maximize machine utilization and throughput to accelerate lead times;

- Our QA team can easily evaluate your finished parts to guarantee that they are within spec and meet your requirements.

In short, our secure, network-connected production environment allows us to provide custom machining services for high-precision parts with short lead times and competitive pricing.

Strategically Implementing Robotics & Automation

To complement our digital workflows and advanced CNC machines, we also strategically use robotics and automation throughout our production facility. For example, our robotic pallet loaders can quickly and efficiently transfer parts in and out of machines, ensuring a seamless transition from part to part while preparing them for post-processing, inspection, and shipment.

Additionally, to ensure that we are able to meet customers’ volume requirements and maximize our machine utilization, our turning and milling operations are set up for lights-out manufacturing, allowing us to manufacture many parts long after our engineers and machinists have gone home for the day.

Enabling Our Skilled Machinists With Digital Tools

But high-end machines and advanced software won’t make great parts by themselves, even with the aid of robotics and automation. High-quality precision CNC machining requires the knowledge and expertise of skilled engineers and machinists who are enabled to do their best work with access to the right technology. That’s why we’ve equipped each of our CNC machines with PC workstations connected to our digital production environment. This ensures that every machinist always has the information they need for every job, and that your part designs and specifications are accurately communicated across our shop floor and always up to date based on your requirements.

Staying Ahead of the Precision CNC Machining Technology Curve

At Coastal Machine & Supply, we believe in being ahead of the curve when it comes to leveraging technology in manufacturing. From driving efficiency in quoting and production to ensuring the accuracy of your parts and the security of your data, technology is central to everything we do. However, even with the best technology and the most advanced CNC machines, our experienced engineers, skilled machinists, and company-wide commitment to quality are what truly allow us to excel.

If you’re looking for a precision CNC machining partner and ITAR manufacturer who has invested in the technology and the people to produce high-quality parts with precision and speed, contact our team or request a quote today. We’d be thrilled to show you what our commitment to using the latest technologies in manufacturing can help you accomplish.