Our friends over at Modern Machine Shop recently published an article about some of the advances that Coastal Machine and Supply has made recently. Take a look at what they had to say!

Many manufacturers find niches supplying single industries, especially when those industries have an outsized local footprint. However, supplying parts for an end market can turn a niche into a rut if that market experiences economic hardships. Many shops have learned to diversify their customer bases over the years, but it can be difficult to ensure a shop is in compliance with the standards of an unfamiliar industry. Some shops are turning toward software solutions to help make up for this lack of experience in different end markets.

Navigating Shifting Markets

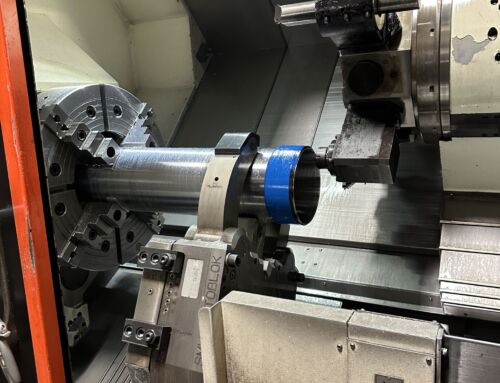

Founded in 2004, Coastal Machine & Supply in Carencro, Louisiana, has spent most of its existence servicing the oil and gas market. Dealing primarily in machining carbon steel, stainless and high-nickel alloys, Coastal benefited from the heavy presence of the oil and gas industry in the state. It tended to focus on large, round parts with milling, turning, threading and boring operations.

The company has a fleet of 12 turning centers, including nine Mazak Quick Turn and Slant Turn lathes, and two Weiler lathes. These turning centers were sufficient for the bulk of the company’s oil and gas work, with help from two Mori Seiki NT4300DCG dual-spindle, eight-axis mill-turn machines.

However, when oil and gas work dried up with due to the COVID-19 pandemic in 2020, Operations Manager Kody Guidry saw it was time to diversify. “Nobody wants to lay off workers because the market isn’t where you need it to be,” he says. “So we decided it was time to get into a new market.”

The shop eventually settled on moving into aerospace machining, but before it could make the move, it needed to achieve AS9100 certification.

Help From the Pros

The aerospace industry relies on AS9100 standards for manufacturing parts. Because lives depend on the accuracy of these components, the standards can have very little wiggle room. For many businesses, applying for certification is a drawn-out process that takes months – or even years – of training, redesigning shop practices and auditing processes. Coastal Machine was fully certified in less than four months.

The secret to the company’s success, according to Guidry, was the ERP system the shop had adopted the previous year.

A potential hire introduced Guidry to Proshop ERP during a job interview, and the company adopted it after a year of evaluation. The switch took about two months, but the company saw immediate benefits. Notable for being designed by an active machine shop for internal use, ProShop combines several software modules into a single package, enabling users to easily access data from around the company. This means that order information, job statuses, material stock and machine availability are all immediately accessible from any device connected to the system.

“We didn’t realize it at the time,” says Guidry, “but we spent a lot of time chasing down work orders. When the due dates changed or there were revisions to the work orders, we’d have to go in, find the work order, reprint and get everything back in the work order packet right away.” With ProShop, updates from any one device will update the information for the entire company, with no need to chase down paperwork. “Everything is there from the instant it changes,” Guidry continues. “It saves a lot of running around.”

This switch happened in 2019. The next year, chaos hit the oil and gas industry, and by September of 2020 Coastal Machine had decided to move into aerospace.

Fortunately, the ERP system simplified the process dramatically. “ProShop has a lot of AS9100 built into the system already,” Guidry says. “And a lot of the requirements are there and taken care of if you use the system as it was intended.” Additionally, all AS9102 quote forms are contained within the system. “We input all of our dimensions into ProShop, which generates an AS9102 form and uploads it into the document package,” says Guidry.

To help the company identify which areas needed addressing before the audits, ProShop consultants provided a gap analysis. “When we received our first gap analysis, we had already met 95% of the requirements for certification,” says Coastal Machine Quality Manager Karl Crow, who spearheaded the certification process. “We needed more checklists and documentation, and some of our forms required more specific wording, but most of the work was already done.”

The shop’s first audit took place in November, with the second one occurring in January. In February, Coastal Machine received full certification. Later, it took advantage of similar tools inProShop ERP to register with ITAR.

Shopfloor Updates

To pull off the pivot into aerospace machining, the company needed more than an ERP system — it needed to build its experience in multiple areas. “Machining for aerospace is a whole different animal from oil and gas,” Guidry says. “We’d never worked with aluminum before, never had so many callouts. It was daunting, at first.”

Experience and research quickly overcame most of these stumbling blocks. The company has invested in two DMG MORI five-axis machine centers to compliment its fleet of five Mazak VMCs. It has also invested in new tooling for machining aluminum and tackling more complex geometries. On top of all that, the company has embraced toolpath simulation software. “Every machine tool station has Fusion360 installed on the control,” Guidry says. “We use its toolpath simulation extension before every new run of parts.” This makes it much easier to economically achieve the more exacting tolerances of aerospace customers.

Additionally, the company has invested in new inspection equipment, including a Keyence handheld touch probe. The probe is accurate within 0.002 inches in a 30×16-inch area, and uses cameras along with the touch probe to measure a part’s features. The user begins by taking a picture of the part using the attached camera . With that image, a linked computer highlights where to place the probe to measure the necessary features. The shop also purchased a new Hexagon Global S Bridge CMM installing this month for even more precise part validation. “With oil and gas, this would have been expensive overkill,” Guidry says. Now, exacting quality management is just another step in the process.

Workholding proved to be another hurdle, with the company machining more flat and prismatic parts. Dovetails are a common feature at the shop these days, as is vacuum workholding. Guidry says the shop also makes use of carpenter’s squares for workholding. “We needed to keep the flat parts from moving horizontally, so we keep them in place using two carpenter’s squares at opposite corners,” he says. “Without the squares on the vacuum table, we can’t manage a chipload high enough to be profitable.”

Moving into machining for an entirely new market required the collective effort of the entire shop. Even with help from ProShop, the company needed to adjust to new materials and a more precise approach to machining parts. Photo Credit: ProShop ERP

These kinds of simple, creative solutions are common in the shop. “We knew there was a learning curve going in,” Guidry says. “We didn’t expect to make money on those first jobs due to new types of threads and other stuff we didn’t see in the oil and gas market.” But everyone in the company recognized the need for this shift. “Everybody worked together. We did a lot of research, spoke to the customers to make sure we interpreted everything correctly. We’re still learning.”

Even as Coastal Machine grows into its role as an aerospace provider, the company is not content to keep to these two industries. Instead, it has finished its ITAR registration and is making plans for the semiconductor industry to further diversify its customer base.

ELI PLASKETT, Senior Associate Editor, Modern Machine Shop