When looking for a precision machining partner, not all shops are created equal, even if on the surface they may seem to have similar capabilities. At Coastal Machine & Supply, we’re an AS9100-D and ISO9001 certified machine shop and ITAR-approved manufacturer with extensive experience manufacturing long, large, and complex parts from standard and exotic materials for customers across industries, including within the aerospace and defense sectors.

To manufacture parts with such challenging dimensions and complexity for customers who require absolute precision, it takes not only skill and experience but also the right equipment.

We’ve made significant investments to scale our capabilities and capacity in order to take on the most challenging CNC machining projects for the most demanding applications. Whether you require precision aerospace and defense components manufactured to exacting standards or large, long parts for applications in the oil and gas industry, we’re equipped with the tools, expertise, and a “never back away from a challenge” attitude to manufacture the parts you need with incredible precision.

Turning Long Precision Parts With Large-Format CNC Lathes

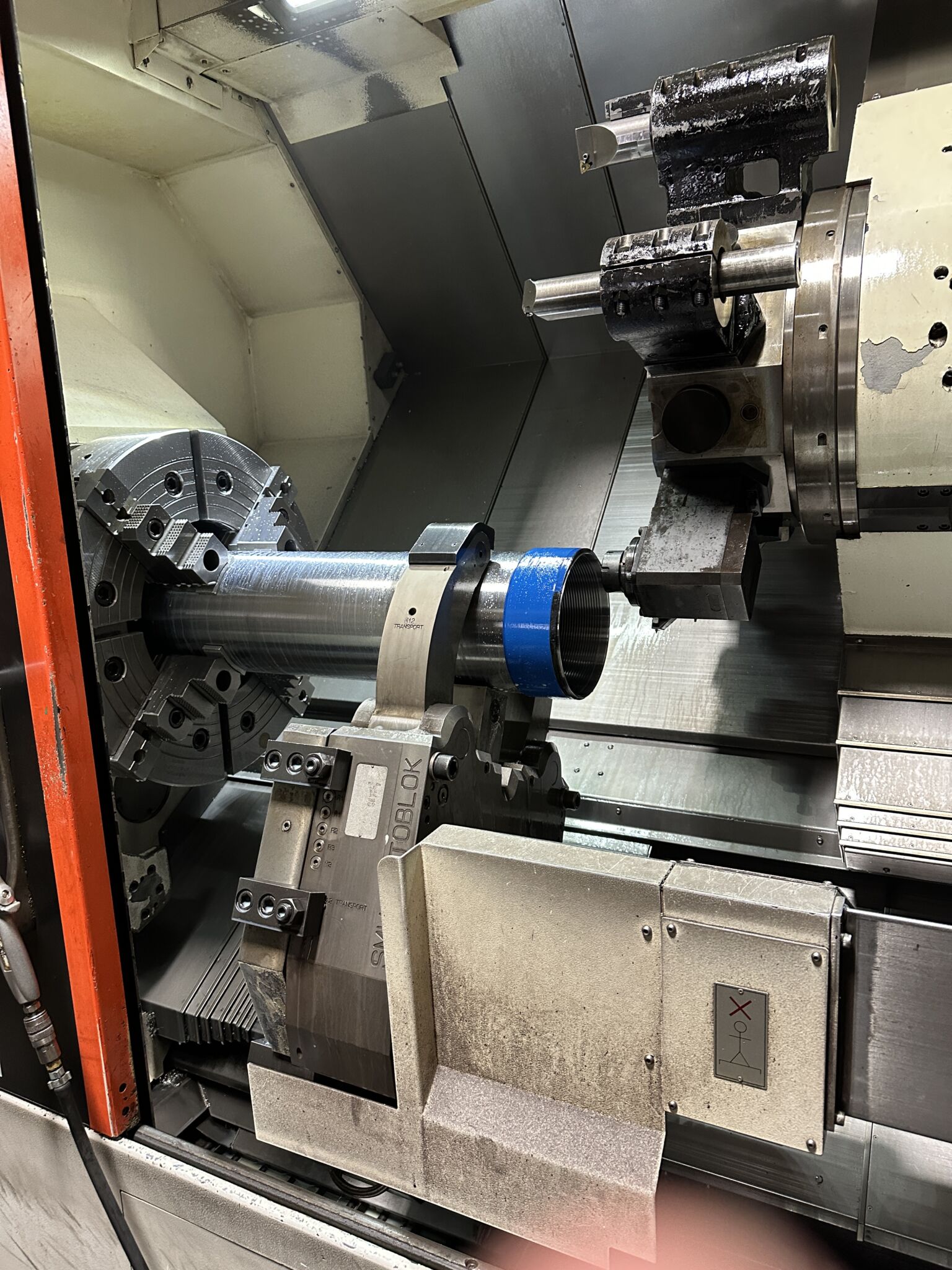

Like most machine shops, CNC turning is one of our core capabilities. But what sets us apart when it comes to turning is the size of the parts we’re able to manufacture and the precision with which we can do it.

Our state-of-the-art production facility with lights-out manufacturing capabilities is equipped with a wide array of CNC turning machines, including six Mazak slant turns and a Weiler E70. These CNC machines are able to turn long parts up to 120” between centers to tolerances of 0.001”. Though we’re experts at using these machines to produce liner hangers, packers, and pup joints for customers within the oil and gas industry, or missile bodies and motor cases for defense applications, we’re prepared to manufacture any part of a similar shape or size.

However, if your parts are longer than 120” with an outside diameter (OD) of less than 12”, we have a solution: we can position your parts to extend outside of the machine and, in some cases, even beyond the walls of our building! Though this might seem non-traditional, and in many ways it is, letting your parts partially sit outside the confines of the machine will not affect their quality or dimensional accuracy — it’s just a strategy we’ve developed to machine extremely long parts.

When manufacturing long parts, boring deep holes can also present a challenge. The deeper the hole, the longer the boring bar needs to be; however, long boring bars can vibrate, creating what’s known as chatter, resulting in unacceptable surface finishes or tolerances that are out of spec. To combat this, we’ve invested in high-end carbide anti-vibration boring bars, which allow us to bore holes up to 15 times the diameter of the tool without chatter. This means that even if your design includes deep holes with tight tolerances, we’ll be able to produce these features with great surface finishes and superb dimensional accuracy.

Machining Large & Complex Parts With Advanced 5-Axis Mills

geometries. In addition to multiple, smaller 5-axis CNC milling machines, our DMG MORI Seiki 5-axis Champion allows us to manufacture precision parts at tolerances of 0.0001”. While large parts with such tolerances may not be standard within most industries, when manufacturing parts like satellite and rocket components, launch pad structure systems, and spacecraft engine components, this level of precision is essential.

Beyond milling, our 5-axis CNC machines are also equipped with vertical turning lathe (VTL) capabilities, allowing us to easily turn shorter parts (under 20”) with diameters that are too large for our lathes. Additionally, with the VTL on our 5-axis mills, we can more efficiently manufacture medium- to large-sized complex parts that require both turning and milling in fewer setups, reducing both machine time and cost.

Equipped for Size, Dedicated to Precision & Excellence

At Coastal Machine & Supply, we specialize in undertaking complex projects that other machine shops can’t or simply don’t want to handle. With advanced CNC milling and turning capabilities that allow us to machine long, large, and complex parts for critical applications, we’ve become experts at navigating the challenges that come with manufacturing, particularly for highly regulated industries.

As a Louisiana manufacturer situated on five acres of land, we’re in the middle of it all — especially when it comes to serving the oil and gas and aerospace and defense industries — and we’re continuously expanding our operations and capabilities to meet our customers’ needs. If you’re seeking a manufacturing partner that values collaboration and communication and is dedicated to precision and excellence, give us a call or send us a message.

Request a quote for your next large, complex project and see what Coastal Machine & Supply can help you achieve.