FROM DIY TO CNC

Milling is a type of cutting process that uses a rotary cutting tool to remove material from the surface of the product piece. Moved perpendicularly along the cutting access so that cutting occurs along the surface of the cutter, this varies from the rotation access used during drilling. Rotating at a high speed, the cutting tool removes chips from the piece to shape into the desired form or finished product.

Industrious do-it-yourselfers have found some success with the milling process using an at-home drill press to create a DIY approach to process milling, however industrial milling machines provide versatility in the production process and can perform a number of different functions.

USES FOR THE MILLING PROCESS

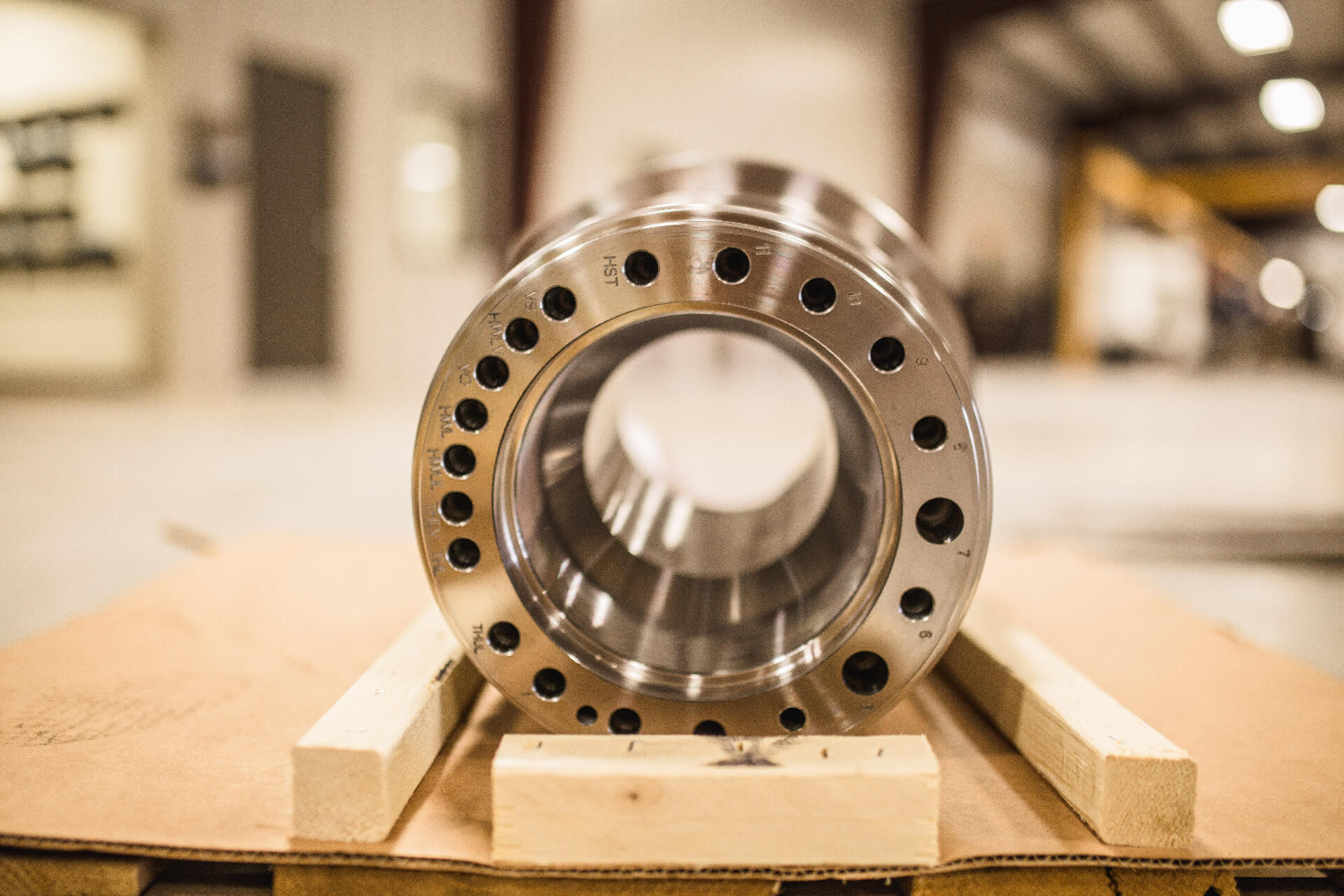

Parts that are fabricated through the milling process are often geometrically unique and have many features and surface contours. Milling allows for pieces to be produced that are asymmetric and can create cuts within extremely high tolerances. From large items to intricate parts, milling can be used for prototype designs, as well as custom parts that only require limited quantities. Three dimensional mold that will be used further along in the production process are often milled, creating a durable, detailed mold that can be used over and over.

USEFUL ACROSS ALL INDUSTRIES

- Aerospace and aircraft

- Automotive

- Commercial

- Electronics

- Industrial and OEM

- Maintenance

- Medical

- Technology and security

- Telecommunications

- Transportation

The milling process differs from lathe tuning in that the workpiece being cut through milling remains stationary. Using small cuts to remove unwanted products from the workpiece, there are three approaches to using a milling machine. The cutter can feature many teeth to remove product, the cutter may spin at a high speed, or the material may progress through the cutter slowly, although it is most common for a combination of these techniques to be used to create the finished product.

CNC MILLING

Technological advances have expended the production capabilities of the milling process by adding Computer Numerical Control or CNC milling machines within the industry. The tools within this machine are controlled by a computerized system taking direction from computerized software codes that can be converted from CAD designs. There are three types of CNC milling machines most commonly used in production today, referring to the number of directions that the cutting tool can operate. CNC Milling is often used as secondary or finish milling for highly detailed components, creating contours, grooves, slots, holes and other complex geometries.

- 3-AXIS MILLING: Composed of a vertical spindle and a horizontal spindle

- 4-AXIS MILLING: Adds a Rotary axis in addition to a vertical and horizontal spindle and is commonly used for aeronautical and automotive parts.

- 5-AXIS MILLING: The cutting tool moves linearly along the X, Y, and Z axes and rotates on the A and B axes to provide cutting along 5 sides of the piece at once.

Another benefit of CNC Milling is the ability to process a number of different product stocks with this machine. This allows designers and clients to choose from metals, plastics, ceramics and other materials to mill a product to their exact specifications.

YOUR MILLING EXPERTS

From Aerospace and Defense Industries to Oil and Gas Companies, machine milling increases the capability of providing products of all types and sizes, from smaller to larger diameters and volumes, all while holding tight tolerances and performance requirements.

Coastal Machine & Supply utilizes a variety of equipment in our manufacturing process, meeting the needs of our diverse clientele with unmatched precision. Each machine, from lathes to milling machines and our fully computerized workflow is an essential contributor to the functionality of our manufacturing process and our ability to provide clients with highly detailed and specialized designs.