PRECISION, EFFICIENCY, AND INNOVATION

Technology continues to bridge the gap between imagination and reality. One such groundbreaking advancement is the integration of Computer-Aided Design (CAD) in the machining process. This transformative approach that empowers engineers and designers to seamlessly transition from digital designs to physical parts with precision and efficiency.

Can a CNC Machine Read CAD Files?

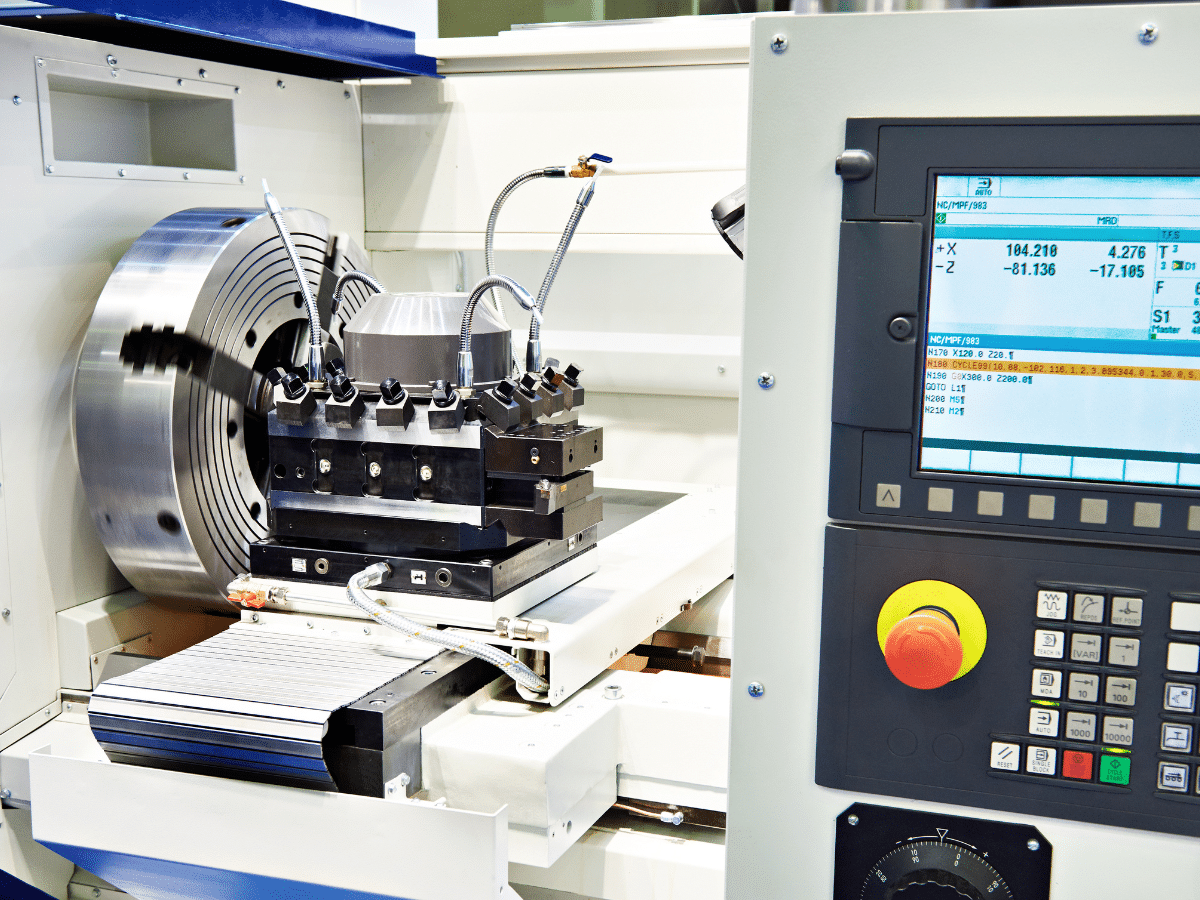

The heart of modern machining beats in the Computer Numerical Control (CNC) machine, an automated marvel that transforms raw materials into intricate parts. But how does this sophisticated machinery interpret the complex designs generated through CAD software?

The answer lies in the relationship between CAD and CNC. CAD software enables designers to draft detailed, 3D models of their envisioned components. These models, saved as CAD files, contain precise information about dimensions, geometries, and even material properties. The pivotal moment arrives when these CAD files are fed into the CNC machine. These machines are primed to translate the digital designs into physical actions, carving away material with incredible accuracy to create the final product.

From CAD to Machining: A Seamless Transition

- Design Phase: Blueprinting the Future: The journey begins in the digital realm. Engineers and designers utilize CAD software to meticulously draft every detail of the component they’re creating. They can experiment with various geometries, sizes, and configurations, ensuring they achieve the desired functionality.

- CAD File Creation: Digital Blueprint: Once the design is complete, the CAD software compiles the information into a CAD file. This digital blueprint holds all the essential data the CNC machine requires to transform it into reality.

- CAM Programming: Bridging the Gap: CAM (Computer-Aided Manufacturing) programming acts as a translator between CAD and CNC. This crucial step involves generating a set of instructions that guide the CNC machine’s movements. It defines the tool paths, cutting depths, and speeds required to craft the part accurately.

- Machine Setup: Preparing for Production: Before the magic truly begins, skilled machinists prepare the CNC machine for production. This involves securing the raw material, mounting the necessary tools, and loading the CAD file along with the CAM instructions into the machine’s control unit.

- Machining Process: Where Digital Meets Physical: With a press of a button, the CNC machine springs to life. It reads the CAD file and CAM instructions, then masterfully executes a series of precise movements. Cutting tools carve away excess material, layer by layer, until the envisioned part takes shape.

- Quality Control: Ensuring Perfection: Machined parts undergo rigorous quality control to ensure they meet the intended specifications. Skilled inspectors use various techniques, such as measurements and visual inspections, to verify accuracy and consistency.

- Final Product: From Pixels to Tangibility: What began as pixels on a computer screen is now a physical masterpiece. The machined part stands as a testament to the harmonious dance between digital innovation and mechanical craftsmanship.

Advantages of CAD Machining

Unparalleled Precision: CAD machining leaves little room for error. The digital design is translated into tangible reality with microscopic accuracy, leading to components that fit together seamlessly and function flawlessly.

Enhanced Efficiency: Gone are the days of manual measurements and trial-and-error machining. CAD machining streamlines the process, minimizing material waste and significantly reducing production times.

Iterative Design: CAD software allows designers to experiment with multiple iterations of a design without the need to physically create each prototype. This freedom fosters innovation and accelerates the development cycle.

Complex Geometries: CAD machining thrives in crafting intricate geometries that would be near-impossible through traditional manufacturing methods. This opens doors to new design possibilities previously deemed unattainable.

Digital Prototyping: Before a single chip of material is cut, CAD machining enables the creation of virtual prototypes. Design flaws and interferences can be identified and rectified in the digital realm, saving both time and resources.

Coastal Machine & Supply harnesses the power of digital design to craft components with unmatched precision and efficiency. Taking digital dreams to physical realities, one thing is certain: advancements in CAD and machining technology are reshaping the world of manufacturing as we know it.