The American defense industry is responsible for the development and production of some of the most advanced military equipment in the world. The industry relies heavily on the use of precision manufacturing technologies such as CNC machining to create complex and critical parts for military applications.

Our Capabilities

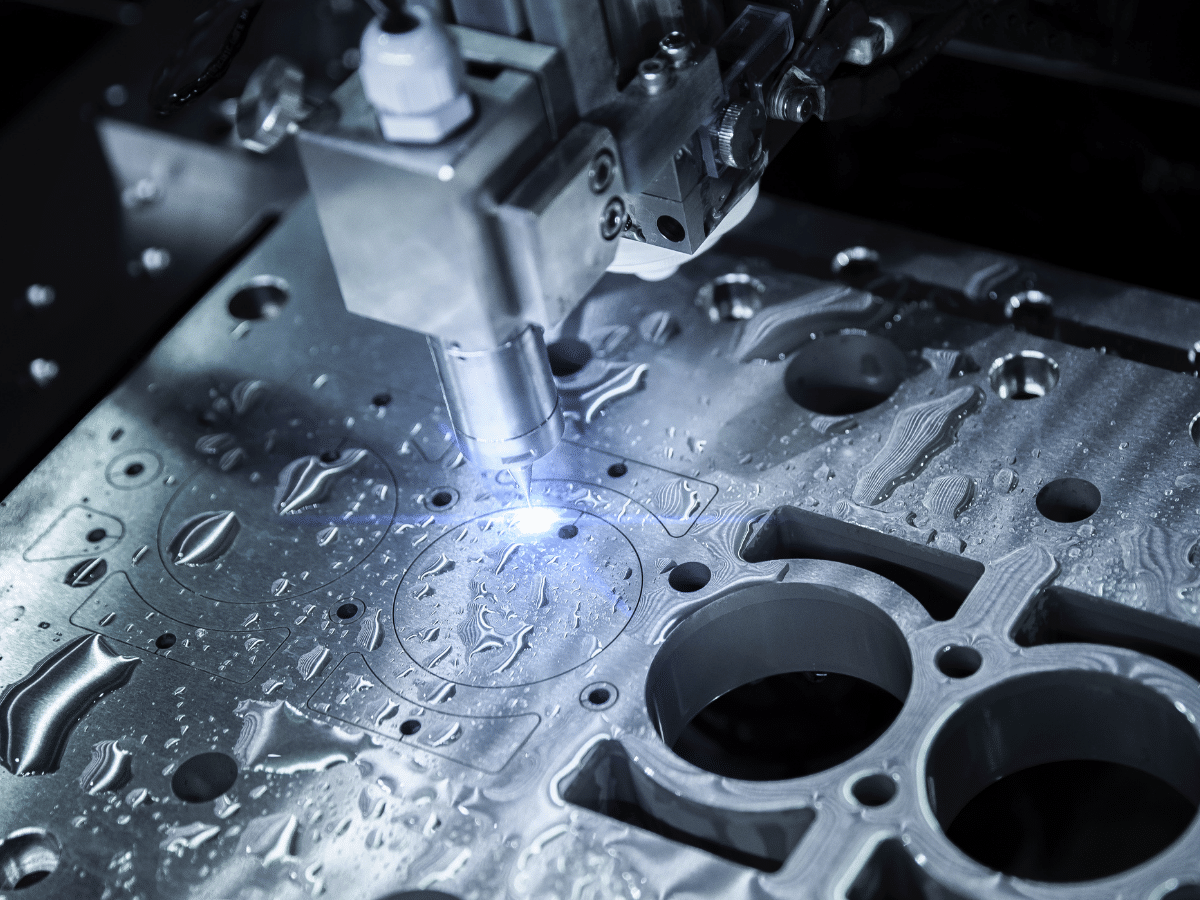

Coastal Machine & Supply’s production facility provides state-of-the-art equipment and technology to our customers. Our 36,000 square-foot facility is equipped with modern CNC machines, advanced tooling, and other cutting-edge technologies, enabling us to provide high-quality machining services that meet our customers’ exact specifications. Our climate-controlled environment ensures that all equipment and products are protected from rust and other environmental hazards, while our secure gated yard provides a safe and private environment for both our customers’ equipment and our facility. This provides our customers with peace of mind, knowing that their valuable equipment and products are secure and protected.

At our facility, we understand the importance of quality and precision when it comes to CNC machining for aerospace and defense contractors. Our commitment to excellence is reflected in our ISO 9001:2015 certification, which ensures that we meet the highest quality standards for manufacturing. Our CNC machining services are designed to meet the specific needs of the American defense industry and our staff has the expertise and experience to produce complex parts with tight tolerances that meet the rigorous standards set by the military. Our state-of-the-art machines and skilled technicians allow us to produce parts quickly and accurately, ensuring that our customers receive their orders on time and within budget.

Digital Ecosystem

One of the significant benefits of a digital ecosystem in CNC machining is complete traceability from the beginning to the end of projects. A digital system allows for easy tracking and monitoring of the manufacturing process, providing complete transparency and accountability for all parties involved. This means that every stage of the process can be traced, and any issues or problems can be identified and addressed quickly.

In addition, going paperless in CNC machining eliminates the risk of losing critical documents. In a traditional paper-based system, documents can be misplaced or damaged, leading to delays, errors, and potentially costly rework. With a digital ecosystem, all documents are securely stored and accessible, ensuring that nothing gets lost or misplaced. This improves efficiency, reduces the risk of errors, and saves time and money for both the machining company and the defense contractor.

Confidentiality

Tantamount to our production facilities and digital ecosystem, confidentiality is of utmost importance when it comes to American defense manufacturing. Machining companies that work with defense contractors must adhere to strict confidentiality agreements to protect the information they handle and ensure that their manufacturing processes are secure and free from any breaches that could compromise the confidentiality of the products they produce. This includes measures such as secure storage, restricted access to sensitive areas, and the use of secure digital systems for all communications and documentation.

Work with Coastal Machine & Supply

At Coastal Machine & Supply, we take pride in contributing to this important industry by providing high-quality CNC machining services for defense contractors and other manufacturers. That’s why we have established strict protocols and measures to ensure the confidentiality and security of all products and information we handle. From secure storage to secure digital systems, we take every possible measure to protect our customers’ sensitive information and equipment. We take great pride in the quality of our work, and we strive to exceed our customers’ expectations with every order. As a result, we have built long-term relationships with many defense contractors and other manufacturers who rely on us for their CNC machining needs.