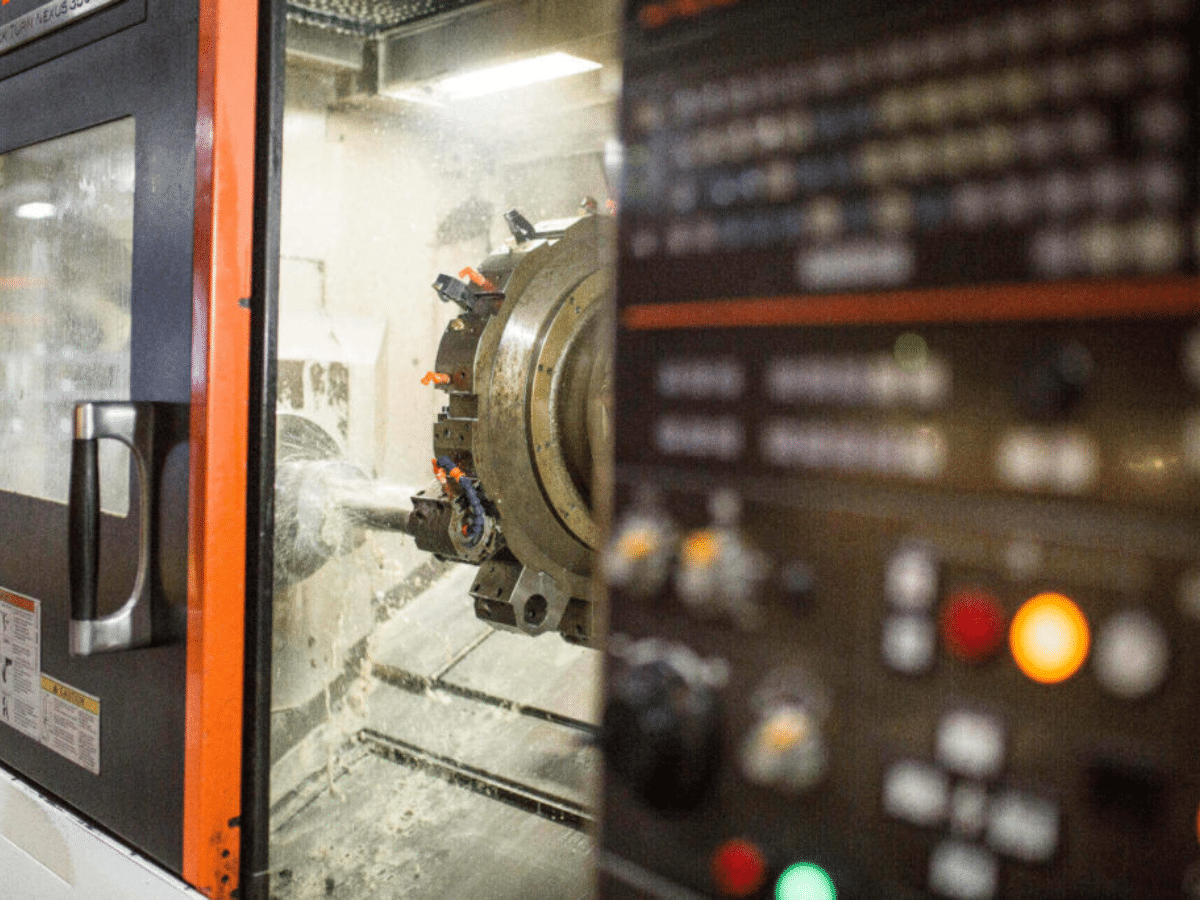

Optimizing Efficiency in Production

In today’s fast-paced manufacturing industry, companies are constantly seeking innovative solutions to stay ahead of the competition. Multi-axis machining has emerged as a game-changer, offering unmatched precision, versatility, and efficiency.

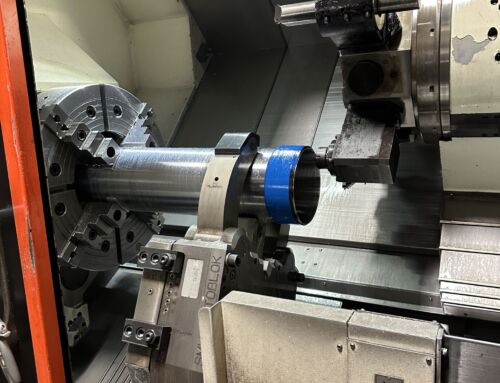

Multi-axis machining refers to a manufacturing process that involves the simultaneous movement of a cutting tool along multiple axes to create complex and precise machined parts. Traditional machining processes typically involve movement along three axes (X, Y, and Z) to perform operations such as milling, drilling, and turning. In contrast, multi-axis machining utilizes advanced computer numerical control (CNC) machines that can move the cutting tool along additional rotational axes (A, B, C) to achieve greater flexibility and precision.

By adding rotational axes, a multi-axis CNC machine enables the cutting tool to approach the workpiece from various angles and orientations. This capability allows for the creation of intricate shapes, contours, and undercuts that would be challenging or impossible to achieve using traditional three-axis machining.

Empowering Innovation

Designers and engineers can push the boundaries of traditional manufacturing techniques, unleashing their creativity and bringing innovative ideas to life.

Unparalleled Precision:

Multi-axis CNC machines excel in delivering precise and complex geometries with exceptional accuracy. By enabling simultaneous movement along multiple axes, these machines can achieve intricate cuts and contours that were once difficult to achieve. The ability to maneuver the cutting tool dynamically enhances precision and ensures consistent quality throughout the production process.

Enhanced Efficiency:

Multi-axis machining eliminates the need for multiple setups and manual repositioning of the workpiece. With the ability to perform various operations in a single setup, manufacturers can significantly reduce downtime and increase productivity. Additionally, multi-axis CNC machines allow for optimized tool paths, maximizing material removal rates. This means faster production cycles, reduced lead times, and improved overall efficiency.

Improved Spindle Tooling:

Multi-axis machining enables the use of a wide range of cutting tools and spindle configurations, enhancing flexibility in machining operations. The ability to approach the workpiece from different angles allows for more efficient machining and improved access to hard-to-reach areas. The dynamic movement of multi-axis CNC machines reduces the occurrence of tool marks and surface imperfections. With smoother cutting paths and reduced vibrations, manufacturers can achieve superior surface finishes, eliminating the need for additional post-processing.

Rapid Prototyping:

Multi-axis machining accelerates the prototyping process by enabling simultaneous and complex machining operations. Manufacturers can quickly produce and evaluate prototypes, allowing for faster design iterations and improved time-to-market. Multi-axis CNC machines empower designers to create intricate and geometrically complex prototypes. This capability opens doors to innovative designs that were previously limited by traditional machining techniques.

Cost Savings:

The precision and accuracy of multi-axis machining minimize material waste, resulting in lower scrap rates. Manufacturers can optimize material usage, leading to cost savings and increased profitability. With multi-axis machining, manufacturers can consolidate multiple machining operations into a single setup. This reduces the need for additional secondary operations, such as repositioning, re-fixturing, and manual adjustments. The streamlined process saves time, labor costs, and reduces the risk of errors.

A New Era of Manufacturing

Multi-axis machining has revolutionized the manufacturing industry, offering a host of benefits to companies seeking precision, efficiency, and innovation. From spindle tooling advancements to rapid prototyping capabilities, the advantages of this technology are undeniable. As competition continues to intensify, adopting multi-axis CNC machines becomes crucial for businesses aiming to stay ahead in today’s market.

Embrace the power of multi-axis machining and unlock new possibilities for your manufacturing processes. Coastal Machine & Supply is your trusted partner in delivering cutting-edge machining solutions. Contact us today to learn more about how multi-axis machining can transform your production capabilities and drive your business forward.