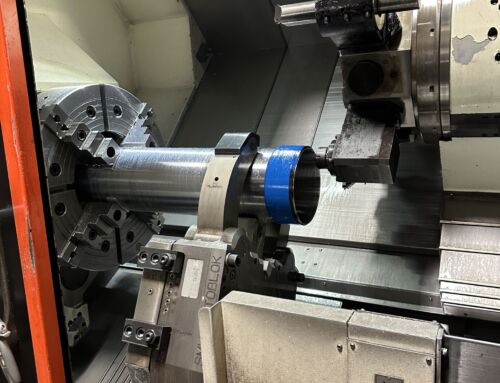

Utilizing the latest equipment and technology for Lathe Machining, Coastal Machine Supply has recently expanded our machining capabilities with the addition of a Mazak Powermaster w/ SmoothG Control lathe. Featuring innovative specifications that includes 24” 4-Jaw Chuck – 12 ½” Thru Hole – 120” between centers, this lathe allows us to meet the ever-changing needs of our clients across various industries. If you’re new to lathe machining, let’s review a few of the basics that should help you understand our excitement about this new machine acquisition.

What Is A Lathe Machine Used For?

Used primarily to shape metal or wood by rotating the product around a stationary cutting tool or blade, a lathe removes the unwanted parts of the material to create the design. The basis for the production of many parts, a lathe is a versatile tool that offers precision shaping, drilling, sanding, knurling, turningm, cutting, and deformation for both woodworking and metalworking.

What Is Machining On A Lathe Known As?

Tuning is the common name for machining on a lathe. Using different attachments and accessories that attach to the spindle of the lathe, an assortment of chucks and centers are used to perform various functions to create the finished product.

What Are The 3 Types Of Lathe?

What Is The Difference Between Milling And Lathe?

In the manufacturing industry, both lathes and milling machines provide essential functions in the production of parts and pieces used in the aerospace and defense industries as well as in oil and gas exploration and excavation. Each with their own functions in the manufacturing process, Coastal Machine and Supply utilizes both in the production of our products.

The easiest explanation is to think of a milling machine and a lathe as the inverse of one another. A milling machine shapes products by removing materials from the workpiece with a multi-bladed cutting tool. With a milling machine, the workpiece remains stationary, whereas with a lathe, the workpiece moves and a singular cutting tool remains fixed. Milling machines are taller than lathes, and since they are shorter in length, they make up a smaller footprint and require less room on the manufacturing floor. Consisting of a bed, headstock, tailstock, spindles, tool rest and motor, the distance from the main spindle to the bed determines the maximum diameter of products that can be machined on a lathe. The introduction of our new lathe expands our production capabilities with an additional lathe that accommodates 120” between centers!

The use of Mazak’s SMOOTH TECHNOLOGY with our new lathe machine brings speed, accuracy, functionality, and ergonomics to the manufacturing process. Allowing us to maximize our resources, Coastal Machine & Supply offers unmatched service for all our clients. Let’s talk about our production capabilities for your project!